🕸️ I 3D-Modeled and Printed a Real Miles Morales Web-Shooter (and Yes, It Actually Works)

You know that feeling when an idea from a movie keeps living rent-free in your head?

For me, that idea was Spider-Man’s web-shooter. Ever since I got into 3D design, I’ve wanted to see if something like that could actually work — not just as a prop, but as a real, functional gadget.

So, I decided to build it. From scratch.

This is how I designed, modeled, and 3D-printed a working Miles Morales–style web-shooter, powered entirely by creativity, physics, and a roll of Polymaker PolyLite Pro.

💻 From Concept to CAD: Designing in SOLIDWORKS

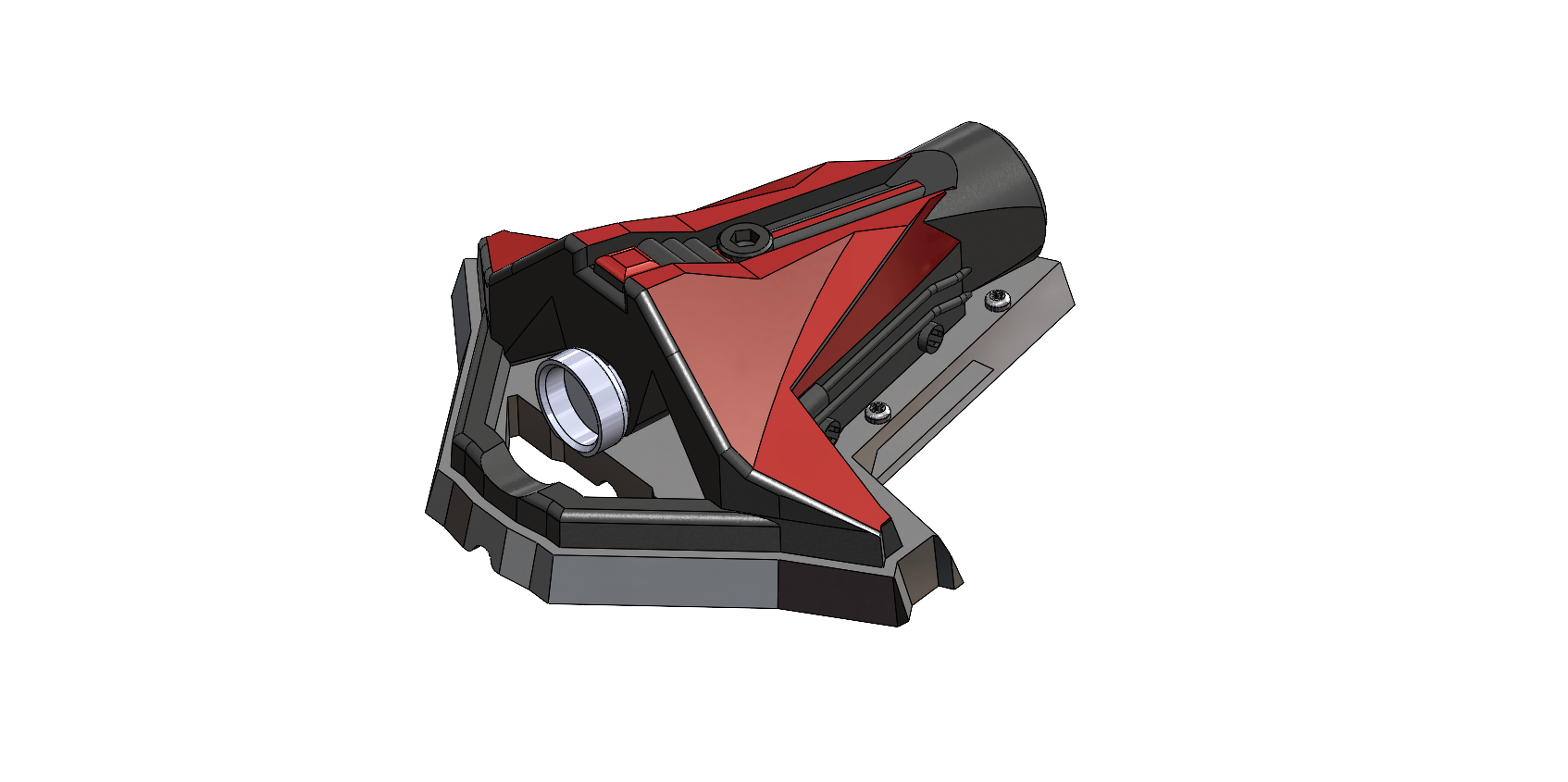

I started by sketching out a few versions of the design and then jumped straight into SOLIDWORKS to bring it to life.

The model needed to hit a delicate balance between ergonomics, structure, and mechanical function.

The final design included:

an ergonomic shell that fits snugly around the wrist,

a central chamber for the firing mechanism,

and modular side mounts so I could quickly swap or test new parts between iterations.

One of the biggest design challenges was making it both good-looking and mechanically sound — something that could have stepped out of a Marvel film, but still printable and durable enough for real-world use.

🧩 Printing with the Prusa MK4 + PolyLite Pro

Once the CAD model was ready, I moved over to my Prusa MK4 to start printing.

I used Polymaker’s PolyLite Pro filament, which has that sweet spot between strength and flexibility — perfect for parts that need to lock, snap, and flex just enough under tension.

Printing specs:

Layer height: 0.2 mm

Infill: 30% gyroid (solid enough for impact, light enough to wear)

Temperature: 210°C nozzle / 60°C bed

Supports: minimal, mostly under the central chamber

The first few prototypes looked amazing, but some joints and clips were a bit too soft.

That’s when I dove back into SOLIDWORKS, thickened the walls, adjusted tolerances, and reprinted until everything clicked — literally.

🚀 The Mechanism: Real-World Physics Meets Maker Energy

At the heart of the build is a spring-loaded launch system, entirely custom-designed.

No compressed air, no hidden motors — just tension, release, and precision.

3D printing gave me the freedom to tune everything down to fractions of a millimeter, ensuring the moving parts fit together like clockwork.

The first successful test was pure adrenaline.

The filament shot out cleanly, retracted as intended, and for a brief second… I was Miles Morales.

Okay, maybe not swinging between buildings (yet), but the engineering worked — and that’s a win in my book.

🔍 Key Takeaways

SOLIDWORKS + Prusa = unmatched prototyping workflow.

The speed of iteration is insane when your design and print cycle are so tightly connected.Polymaker’s PolyLite Pro is a beast.

Tough, clean prints with just enough flex to survive “maker testing.”Parametric modeling saves time.

When you’re iterating fast, being able to tweak dimensions instead of redrawing parts is a game-changer.

🧠 Why I Built It

For me, this project was never just about making a prop.

It was about pushing design tools to their limits, understanding material behavior, and building something that shouldn’t exist — but now does.

Seeing the parts go from digital model to tangible, working prototype is the kind of satisfaction that makes 3D printing so addictive.

That “I actually built this” feeling never gets old.

🧵 Final Thoughts

This web-shooter is the perfect collision of pop culture, engineering, and creativity.

And it’s a reminder that the gap between imagination and reality is getting smaller — one print at a time.

Big shout-out to Prusa Printers, SOLIDWORKS, and Polymaker for making tools and materials that help bring crazy ideas like this to life.